Ferro Molybdenum

Particle Size: 5-50 mm/ 90% Min.

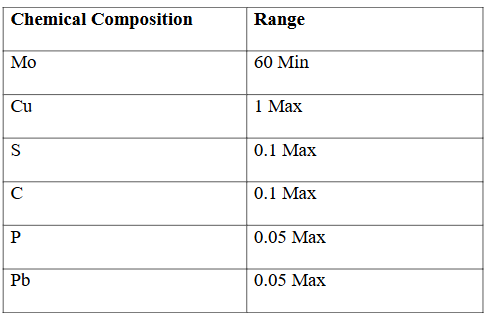

Ferro Molybdenum (FeMo) is a high-quality ferroalloy made from molybdenum (60–75%) and iron (25–40%), produced by smelting molybdenum oxide and iron ore concentrates in a furnace. Known for its ability to improve strength, hardness, and corrosion resistance, Ferro Molybdenum is an essential additive in steelmaking, aerospace, chemical, and metallurgical industries.

As a reliable Ferro Molybdenum supplier, we provide premium-grade material for industrial applications worldwide. For inquiries or bulk orders, contact us at minerals@oranit.de.

Main Uses and Applications of Ferro Molybdenum

Ferro Molybdenum (FeMo) is an essential alloying element widely used across several industries due to its ability to enhance strength, hardness, corrosion resistance, and high-temperature performance. Below are the major industrial applications of Ferro Molybdenum:

1. Steel Industry

The steel industry is the largest consumer of Ferro Molybdenum. It is a crucial additive in producing high-strength low-alloy (HSLA) steel, which is used in construction, automotive components, pipelines, and heavy machinery.

Adding Ferro Molybdenum to steel significantly improves toughness, hardenability, weldability, and corrosion resistance, making it ideal for high-stress and extreme-temperature environments.

2. Aerospace Industry

In the aerospace sector, Ferro Molybdenum plays a vital role in manufacturing jet engine components such as turbine blades and nozzles. Thanks to its exceptional heat resistance and mechanical strength, Ferro Molybdenum ensures reliable performance under extreme temperatures and pressure conditions.

3. Chemical Industry

Ferro Molybdenum is widely used as a catalyst in the chemical industry, especially in processes for producing formaldehyde, acetic acid, and other essential chemicals. Its catalytic properties make it valuable for improving efficiency and reaction stability in various chemical manufacturing processes.

4. Electrical Industry

Due to its high melting point and excellent thermal conductivity, Ferro Molybdenum is used in the electrical industry to produce high-temperature electrical components, including heating elements, filaments, and contacts. These components are designed to withstand intense heat while maintaining electrical efficiency.

5. Metallurgical Industry

In the metallurgical industry, Ferro Molybdenum serves as a raw material for producing other molybdenum-based alloys, such as molybdenum-tungsten and molybdenum-copper alloys. These specialized alloys are used in energy, defense, and industrial equipment manufacturing, where superior strength and heat resistance are essential.

Roasted Molybdenum Concentrates

Particle Size: 0-4 mm/ 95% Min

Roasted Molybdenum Concentrate, also known as Technical Molybdenum Oxide (Tech MoO₃), is an intermediate molybdenum-containing product obtained by roasting Molybdenum Disulfide (MoS₂) concentrate—typically containing 85–92% MoS₂ and 35–37% sulfur—in an oxidizing atmosphere. The roasting process produces a molybdenum oxide with around 57% minimum Mo content and less than 0.1% sulfur.

Globally, approximately 30–40% of Technical Molybdenum Oxide is converted into Ferro Molybdenum (FeMo), while 25–30% is used in producing chemically pure molybdic oxides and molybdates for industrial and chemical applications.

A significant portion of Technical Molybdenum Oxide is also applied directly in steel alloying within electric arc furnaces (EAF) and converter furnaces, achieving up to 3% Mo in EAF and up to 1% Mo in converter steels. Compared with Ferro Molybdenum, Technical Molybdenum Oxide offers lower cost and a faster dissolution rate, making it an efficient choice for direct alloying applications.

For bulk supply or export inquiries, please contact us at minerals@oranit.de.

Rhenium

oranIT GmbH offers 1gr, 2gr, 5gr, 50gr (in a glass bottle), and also bulk packages of Potassium Perrhenate. The specification of the offered Potassium Perrhenate (KReO4) is available in the following table.

For more information and to purchase this product please contact us: minerals@oranit.de.

| CAS | 10466-65-6 |

| Molecular Formula | KO4Re |

| Percent Purity | 99.9% – 99.98% |

| Re | 64.3% |

| K | 13.4% |

| Al | 0.001% |

| Fe | 0.0005% |

| NH4 | 0.008% |

| Ca | 0.002% |

| Si | 0.001% |

| Mg | 0.001% |

| Mn | 0.001% |

| Color | White |

| Physical Form | Crystalline |

| Odor | Odorless |